Electric-Hybrid Vehicle

During the early eighties electric cars were uncommon as fuel was still reasonable but climbing from a stable 30 cents per liter. I was investigating the possibilities of building an electric car for a contest coming up at expo 86 in Vancouver. I looked at pure electric drive system, even though they are attractive from the maintenance and quietness, the battery storage technologies were lagging in efficiency. The lead acid battery was still dominant. I devised a system with regenerative braking, that is taking the lost energy when the brakes are applied and turning them to electricity. After some research, I found that Westinghouse makes a 28 horsepower starter-generator for aircrafts. This is the electric motor that starts the jet turbine on a jet airliner and after the turbine is running, the motor acts as a generator and this drives all the electrical systems on the plane. I checked the specs of this motor and I found that it was designed with aero-space industry in mind as the materials they used to build it made it light and durable and also was very efficient.

At the time gasoline engines were about 30 to 35% efficient at regular city driving, meaning that 65 to 70% of all the fuel that it burns is converted to heat. The efficiency of the diesel motor increased dramatically when driven at a constant speed below 2000rpm. The Westinghouse starter-generator motor produced close to 90% efficiency with a high power curve producing instant torque. What all this means is that, depending on the driving condition, I can use the diesel engine for constant speed like highway driving and the elctric motor for stop-and-go city driving. In that manner I can optimize the battery system and get extended range and efficiency

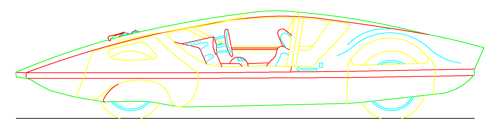

After doing the weight to power calculations I decide to reduce the weight of this car, as you do pay at the pump for every extra pound you carry in your car. I reduced the number of batteries from 20 to 13 deep cycle batteries. I also added a small 3 cylinder diesel engine which was equivalent to the weight of one deep cycle battery. I also decided on using a fiberglass body to reduce the weight and can be easier to fabricate than metal. The frame I used was from a VW Beatle as it easy to work with and has a built-in axle which I can easly modify the gear ratio and adapt the electric motor to it.

This diesel engine will serve three jobs:

- To provide generated electricity to charge the batteries as needed, even while parked at work or shopping.

- To provide extra boost of power to the elecric motor during high demand as in passing on the highway.

- To provide 100% power to the wheels when the current driving conditions demanded constant speed as in highway cruising.

I used a Commodore64 portable computer for my dash display, and an assortment of programs that I wrote to control the balance of power between the diesel engine, the electric motor and the regenerative braking based on driving conditions acquired from sensors that provided relative speed and gear shifting patterns.

The car produced excellent results in city driving and on the highway giving an average fuel performance of 82 miles to the gallon.

The body was to be built of fiberglass with Kevlar strand for light weight and strength. The door entry to the car is composed of fabricating the two doors, windshield and roof as one unit that slides forward along the fenders which enables the driver to walk in and sit down, then the door/windshield/roof unit would automatically slide back shut when the ignition key is activated. Unfortunately the body required more resources than I anticipated and was not able to complete the project in time for the contest.

Hybrid's Today

25 years later, the hybrid concept has matured but I feel that the progress is throttled somehow. The current hybrids are not very efficient and the payback is close to 8 years. The top fuel economy of hybrid is 48 mpg and the SUV hybrid are around 20 mpg. This is not good economics especially when the replacement lithium-ion battery costs as much as $3500 on some models. I feel that m0ost consumers that are in the market to buy a car will not buy the Hybrid as they can get a better return on their investment buying a new or used gas propelled vehicle. And the rest of us will not scrap our cars in a hurry to switch over.

Currently I am in the process of drawing plans for an electric propulsion system that can be easily adapted to any vehicle so that consumers can keep their car and be able to plug this unit to charge overnight. At the current electrical rates, of about 6 cent for a kilowatt/hr, the fuel equivalent should be under 40 cents/liter.